Post-incident investigation of an Embraer E175 found imprints in silicon around the captain’s trim switch, revealing the switch had inadvertently been reinstalled in an inverted position.

Recent incidents and accidents involving failures in aircraft pitch trim systems resulted in forces on the yoke that exceeded the combined physical strength of the two flight crew members. All of these events resulted in uncontrollable pitch gyrations. The accident investigation reports provide important lessons that should be highlighted and reinforced, especially during simulator training.

The first example we explore occurred on Nov. 6, 2019, in an Embraer E175 that had just departed Hartsfield-Jackson Atlanta International Airport (ATL).The captain, who was the pilot flying (PF), was unable to engage the autopilot when the aircraft reached 2,200 ft. MSL after takeoff.

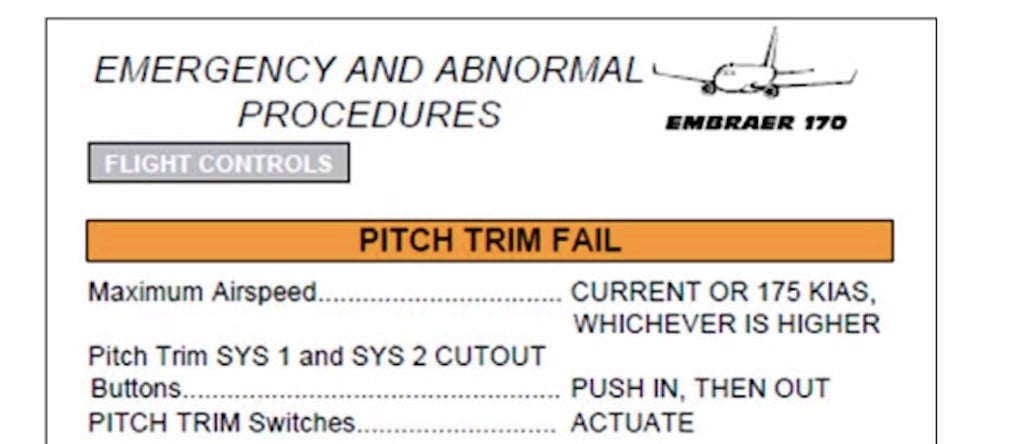

The captain thought that a pitch trim runaway was occurring. He performed the memory item from the Republic Airways’ runaway trim emergency checklist, which was to push and hold the autopilot/trim disconnect button on his yoke. The inordinate control forces forced him to keep both of his hands on the yoke. You will notice that this is a common thread throughout the other pitch-trim failures cited in this article, and it highlights how a flight crew’s attempt to control the aircraft is suddenly jeopardized.

While struggling to control the airplane, the captain asked the first officer to push and hold the autopilot/trim disconnect button on the first officer’s yoke. Neither flight crewmember noticed any changes in the airplane’s pitch condition, and despite both flight crewmembers pushing forward on their respective control columns, the aircraft continued to pitch up.

During the struggle the flight data recorder (FDR) recorded multiple trim-up commands from the captain’s switch, and only one trim-down command from the first officer switch. It doesn’t make sense that the captain be making trim-up pitch commands when the nose was uncontrollably pitching up. That was part of the conundrum faced by the flight crew because the captain was physically moving the trim switch for a nose-down command.

Several severe pitch oscillations occurred, reaching a maximum pitch-up attitude of 27 deg., placing the aircraft perilously close to a stalled condition. The airspeed dropped to 138 kts before they regained control of the airplane.

The captain selected the cutout button for the pitch trim system on his yoke, and the first officer was able to use his trim switch to pitch the airplane down to a normal attitude. Three minutes later, the captain took back control of the airplane, but the E175 again went into a mis-trimmed condition during which the FDR recorded multiple pitch trim up commands from the captain’s trim switch. The first officer resumed control of the airplane. The airplane was controllable in a trimmed condition at this point and able to return for an uneventful landing.

Inadvertently Inverted Switch

Safety investigators discovered that the Engine Indicating and Crew Alerting System (EICAS) provided a “PITCH TRIM SW1 FAIL” advisory message on the morning of this incident. Maintenance personnel had partially removed the switch then decided to defer the maintenance in accordance with the aircraft’s minimum equipment list.

The switch was reinstalled and placarded as inoperative. Post-incident inspection revealed that the captain’s pitch trim control switch had been reinstalled in an inverted position. Since maintenance had been deferred, the chance to discover this incorrect installation was missed because the switch was not functionally tested. Had the functional test been done, maintenance personnel would likely have detected the reversed switch position.

Further examination of the maintenance records showed a history of these failures between Aug. 4, 2019, and the date of the incident, resulting in five replacements of the captain’s pitch trim control switch and two replacements of the horizontal stabilizer actuator control. None of these replacements resolved the pitch trim failures. Subsequent inspection revealed a short circuit in the captain’s pitch trim switch caused by an incorrectly tucked pigtail from the safety wire. This certainly brings to light the importance of adequate troubleshooting by maintenance technicians when the same problem keeps occurring.

The Human Factors Factor

The preceding incident serves as a good example to illustrate key human factors when a flight control system malfunctions. Rule No. 1 in any aircraft emergency is to maintain control of the aircraft. However, trying to regain control of an airplane that isn’t behaving normally confronts pilots with not only the physical difficulty of struggling for control, but the cognitive conundrum of trying to problem solve.

It is unrealistic to expect a pilot to troubleshoot an underlying problem causing unusual aircraft motions while struggling to control an aircraft that isn’t behaving in a predictable manner. In the incident at ATL, the captain would have had to recognize that his trim-down inputs were causing trim-up commands to effectively control the reversed pitch trim system.

Although the switch was not deactivated, it was not supposed to be used according to the MEL instructions. The human factors team member on the NTSB accident investigation noted: “Highly practiced behavior, such as making inputs to keep an airplane in trim, can result in typical motor actions being made automatically despite higher-level knowledge indicating that such action might not be appropriate.” In other words, this was second nature to use the trim switch.

Expectancy means that we react more rapidly and accurately to situations in which we anticipate certain actions or events as opposed to a situation in which the events are a surprise. For example, when we activate the trim-down switch, we expect the forces on the yoke to make it easier to pitch the nose down. There is a real danger when there is a mismatch between the pilot’s expectation and reality. This is especially the case when is aircraft is behaving in a sudden and threatening manner but is not responding normally to the pilot’s control inputs.

Abrupt, unanticipated motions can overwhelm a flight crew. The sensory systems are poorly suited to abnormal accelerations and can overwhelm the body’s sensory, vestibular, proprioceptive, and motor mechanisms. Some surprises, such as an abrupt pitch trim failure, can cause aircraft motions that can overwhelm the body and interfere with a pilot’s ability to focus vision and make accurate, fine-tuned appropriate corrective movements.

Fortunately, this incident ended without harm to any passengers, but it illustrates multiple failures in the aviation system. Even though the MEL allowed deferral of this inoperative component, this incident illustrates the vital role that a normally-functioning trim system provides to the control of the aircraft.

Secondly, the possibility of placing a critical flight control component in an inverted position should have been analyzed during a proper Failure Modes and Effects Analysis in the design stage resulting in proper steps being taken to prevent this from happening. The Failure Modes and Effects Analysis is typically done by engineers with specializations in reliability or systems engineering.

This is an example in which the input from a deep thinking pilot/instructor with a human factors background would provide a much needed perspective on whether an inoperative component should be allowed to be deferred. Furthermore, the removal and installation of any component in a flight control system should require a functional check. These perfectly aligned “holes in the Swiss cheese” allowed this error to continue undetected, thus placing the flight crew in a desperate control for their aircraft.

Did the backgrounds of the two pilots contribute to the fatal crash of a Cessna Citation 550 air medical flight? We discuss in Part 2 of this article.

Comments